A reliable integrated production system that achieves high quality and low cost.

We strictly control all processes from raw material processing to finishing.

In order to provide high-quality products more speedily and at lower cost, it is necessary to implement integrated production from raw material processing to finished-product processing in-house. We have been working on building an "automated, integrated production system" from an early stage. We will continue to improve our production processes in order to respond to the diversifying and increasingly precise needs of our customers.

Pinion Gear

Cutting and drilling process

Round bars are cut to specified sizes and holes are drilled in the inner diameter.

Lathe process

The outside diameter, inner diameter and end face are machined using lathe, and finished to the size of the product.

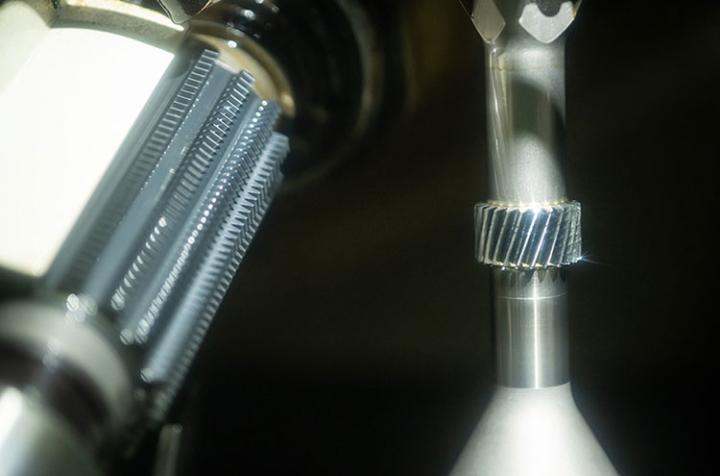

Hobbing

Tooth cutting processing is performed with a hobbing machine.

Allows processing with high precision and speed.

Chamfering process

This process removes burr generated during hobbing.

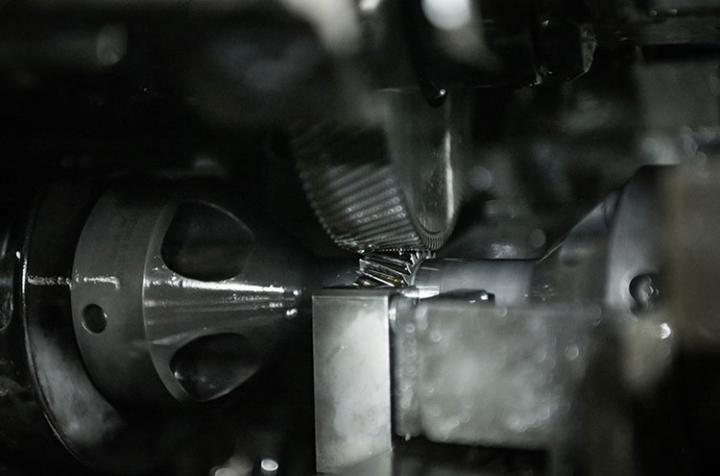

Shaving process

The tooth surface is finished using shaving.

Since the tooth surface is finished before heat treatment, the target value is set considering distortion caused by heat treatment.

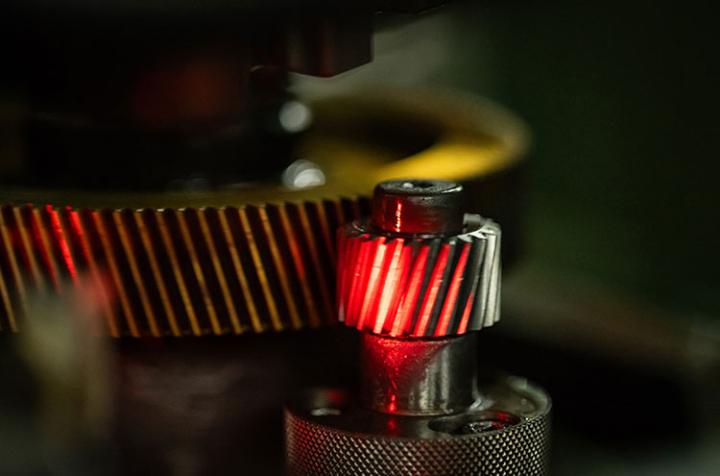

Heat treatment process

Carburizing treatment is applied to increase surface hardness and enhance product strength. At the same time, we perform shot blast treatment to remove scale and burrs.

End surface grinding process

The end face is ground with an end face grinder to provide finishing to the total length dimension and surface roughness.

Inner diameter grinding process

The inner diameter is ground using a honing machine to provide finishing to the inner diameter dimensions and surface roughness.

Cleaning process

Foreign matter is removed using a cleaning machine, followed by application of anti-rust oil.

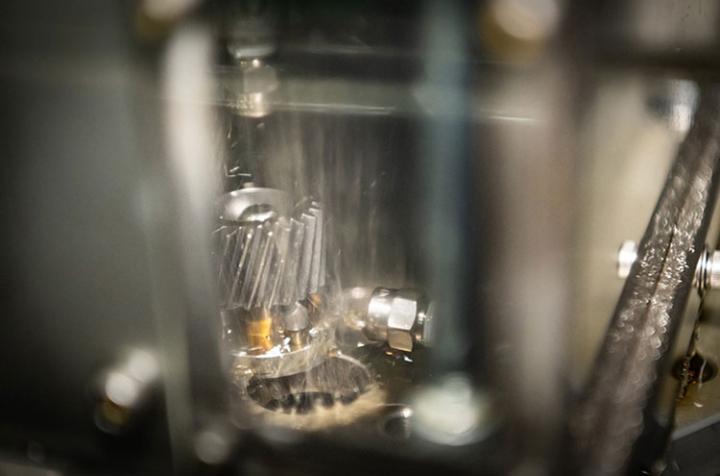

Meshing inspection process

A dedicated gear checker performs meshing inspection and check all gears for dents and scratches.