A reliable integrated production system that achieves high quality and low cost.

We strictly control all processes from raw material processing to finishing.

In order to provide high-quality products more speedily and at lower cost, it is necessary to implement integrated production from raw material processing to finished-product processing in-house. We have been working on building an "automated, integrated production system" from an early stage. We will continue to improve our production processes in order to respond to the diversifying and increasingly precise needs of our customers.

Sun Gear

- Rolling and forging process

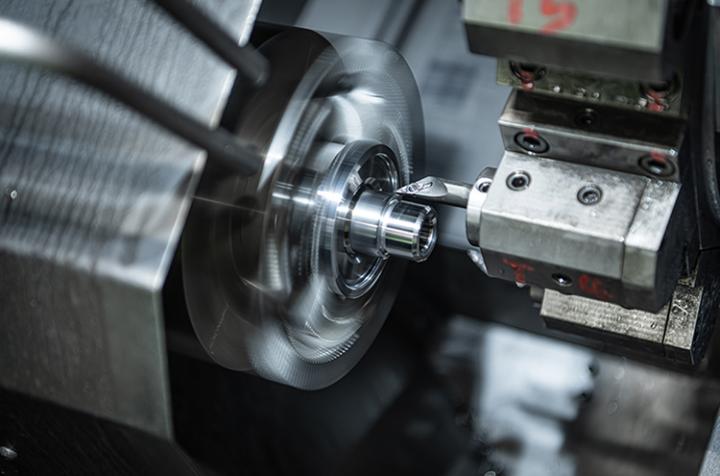

- Lathe process

- Drilling process

- Gear shaping process

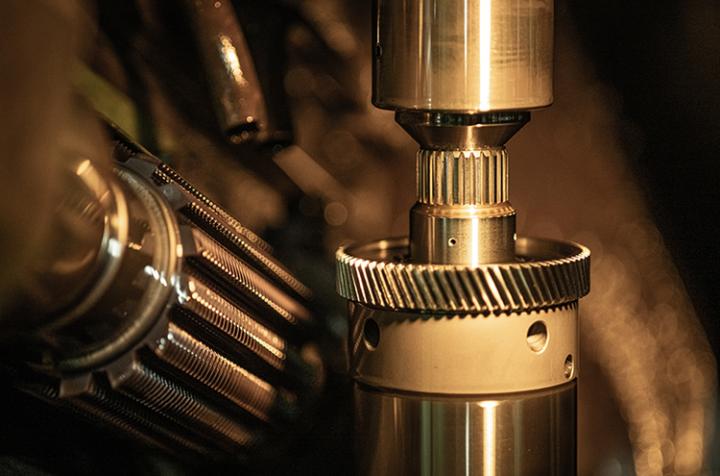

- Hobbing

- Chamfering process

- Shaving process

- Heat treatment process

- Outer diameter grinding process

- Press-fitting process

- Inner diameter lathe process

- Outer diameter superfinishing process

- Cleaning process

- Meshing inspection process

Rolling and forging process

Lathe process

Drilling process

Gear shaping process

Allows cutting of stepped gears or special gears (missing teeth), etc., which cannot be processed by the hobbing machine.

Hobbing

Tooth cutting processing is performed with a hobbing machine.

Allows processing with high precision and speed.

Chamfering process

Shaving process

Heat treatment process

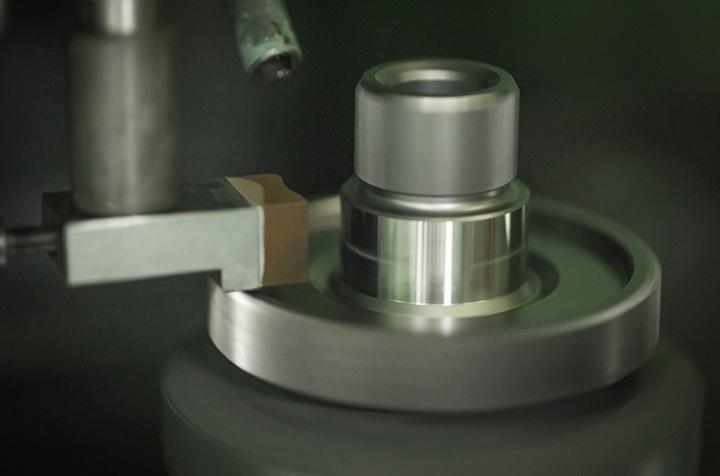

Outer diameter grinding process

The outer diameter is ground with an outer diameter grinder to provide finishing to the outer diameter dimension and surface roughness.

Press-fitting process

Tightly joins parts together with pressure.

Inner diameter lathe process

Outer diameter superfinishing process

Improves the surface roughness finishing performed by outer diameter grinding.