We are working to acquire new processing technologies to meet various gear manufacturing needs.

Maintenance and management of product quality

We monitor the changes in dimensions during processing and changes in distortion due to heat treatment that occur during the manufacturing process, and by feeding the results back into the manufacturing process, we constantly maintain and improve quality.

- (1) Customer drawings are received, target values are determined based on past similar products, and the product is manufactured.

- (2) Processing and heat treatment are actually performed on the production line.

- (3) The amount of change during processing and heat treatment is periodically measured and this amount of change is confirmed.

- (4) Based on the amount of change obtained, the target value of the product is re-set.

We maintain and improve quality by repeating the steps (2) through (4).

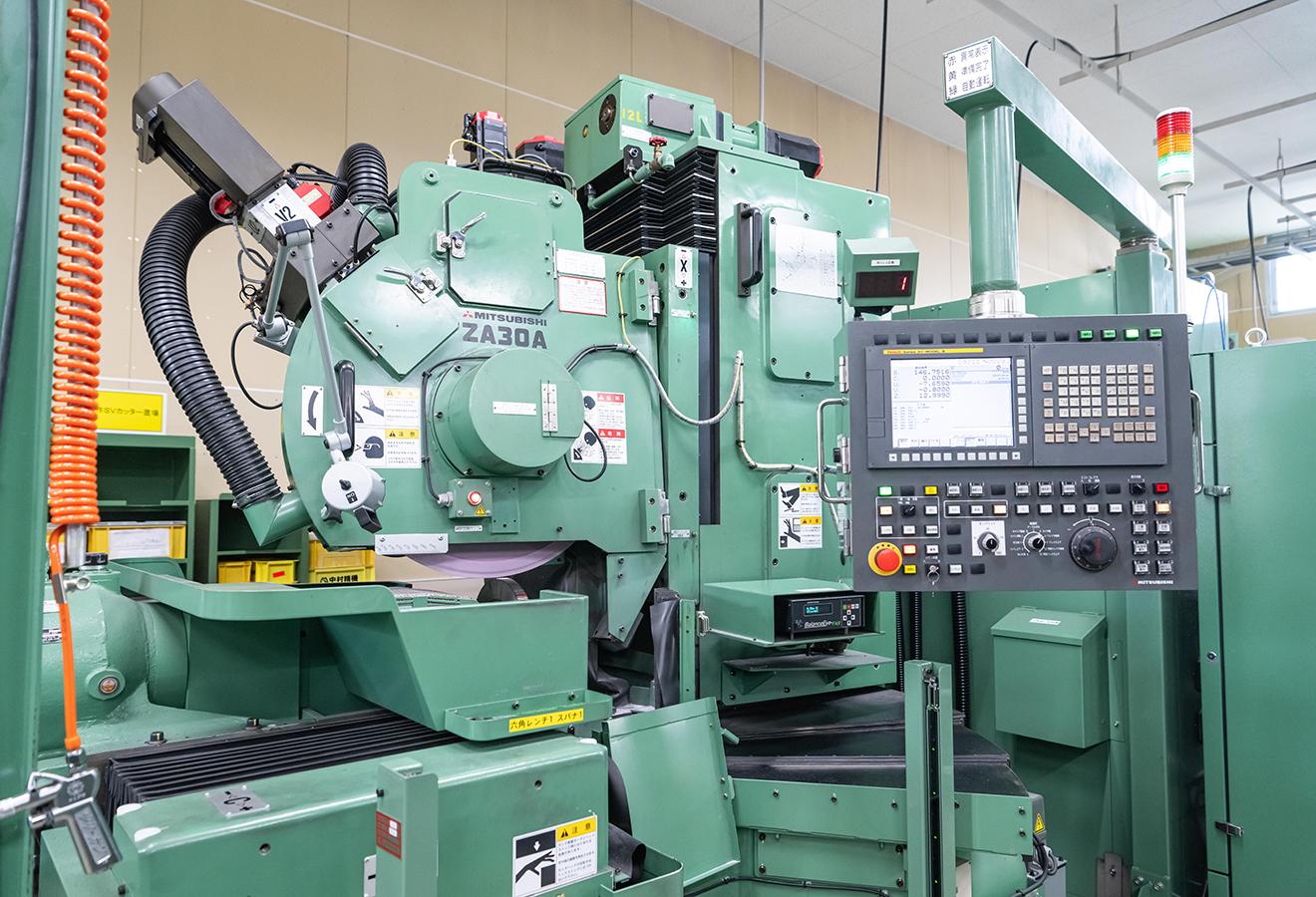

Cutting tool re-grinding

In order to respond quickly and flexibly to changes in product precision, we grind hob cutters, pinion cutters, and drills, and regrind shaving cutters in-house.

GS cutter grinding machine

SV cutter grinding machine

General-purpose chamfering machine

Using NC lathes and complex processing machines, chamfering of both sides of the end face (outer diameter, inner diameter, and grooves) can be done for most gears.