"Building quality into the process" is the foundation of our quality assurance. Defective products are not sent to the subsequent processes.

On the production line, inspections, measurements, and data monitoring are conducted during each process based on clear quality standards. On the automated line, error-proofing devices and automatic measuring devices are installed to prevent the production of defective products, and regular sampling checks are effectively carried out by operators and quality control staff. In addition, a complete examination is also performed as needed.

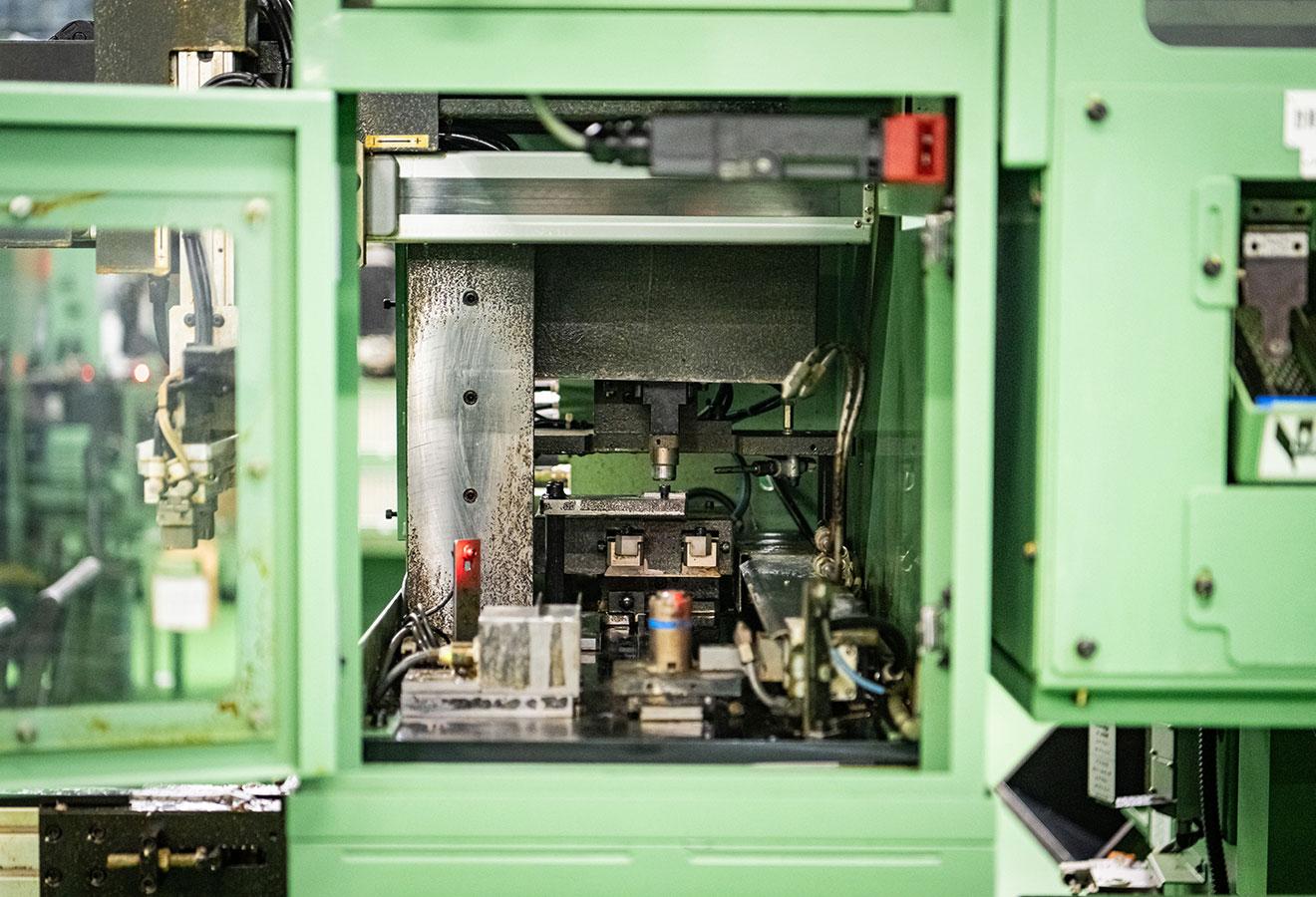

Equipment-based assurance

Our automated production line is equipped with automatic measurement equipment to automatically correct dimensions, image processing equipment to prevent the outflow of unprocessed or visually defective products, and various types of error-proofing devices. Also, a gear checker is installed on the pinion gear production line to perform meshing inspection.

Automatic dimension measuring device for lathe

Gear checker

In-line quality checks

In addition to change control, workers and setup personnel regularly inspect and measure the sample inspection items specified for each process, and checks are also conducted by off-line inspectors at the "quality check stand."

Sampling inspection by workers

Quality check stand

Gear precision assurance

The gear accuracy of the finished product and the amount of distortion during heat treatment are regularly measured by an expert measuring staff member in a temperature-controlled measurement room, and the results are fed back for on-site processing conditions and cutting tool design. As for gear precision, we have several measurement machines that enable the measurement using evaluation methods tailored to customer needs.

CNC 3D measurement machine

NC gear testing machine