Monitoring&Measurement

“Quality must be built into each process” is our basic concept of quality assurance. We do not send any defects on to the next process.

Products are measured and inspected in each process and the results are monitored according to clearly specified quality standards. Poka-yoke devices and automated measuring machines are set up at an automated line to prevent manufacturing defects. Operators and the quality control department regularly carry out efficient sampling inspections and 100% inspection will be carried out if required.

Monitoring By Equipment

Products are measured and inspected in each process and the results are monitored according to clearly specified quality standards. Poka-yoke devices and automated measuring machines are set up at an automated line to prevent manufacturing defects. Operators and the quality control department regularly carry out efficient sampling inspections and 100% inspection will be carried out if required.

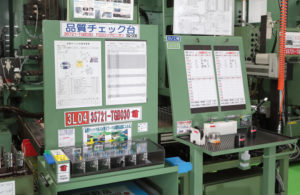

Quality inspection In The Production Line

On production line employees and production line setup personnel check products regularly in accordance with inspection instructions in addition to the measurements for changing controls at setup and the cutter change etc. Using a ‘quality check stand’ other monitoring is carried out by outside inspection personnel at regular intervals.す。

Gear accuracy Quality Assurance

The accuracy of gears and the distortion of dimensions from heat treatment are measured at regular intervals by a specialist inspector in our temperature controlled internal laboratory. The manufacturing conditions and cutter designs are adjusted in relation to these measurements.